There are applications where precision is non-negotiable. In the medical field, it helps in fabricating implants or instruments with micron-level tolerances. In the motor industry, it’s in gear hobbling, the creation of chassis parts, and so on.

The science behind precision motor control is relatively straightforward: making machines move exactly how they’re supposed to during the manufacturing process. Why is this level of precision control so important? Here are a few reasons:

It Prevents Costly Mistakes

Some mistakes can weigh heavily on your business. Even worse, they may cost lives. Say you’re building an airplane engine. Parts that aren’t machined with exact precision are unlikely to fit together properly. This introduces a risk of leaks, overheating, or even catastrophic failure mid-flight.

Or maybe you manufacture pacemakers. These devices help patients regulate their heartbeats. If the components inside the pacemaker aren’t assembled with micron-level precision, they could malfunction. Death and serious health issues then become a stark possibility for the patient.

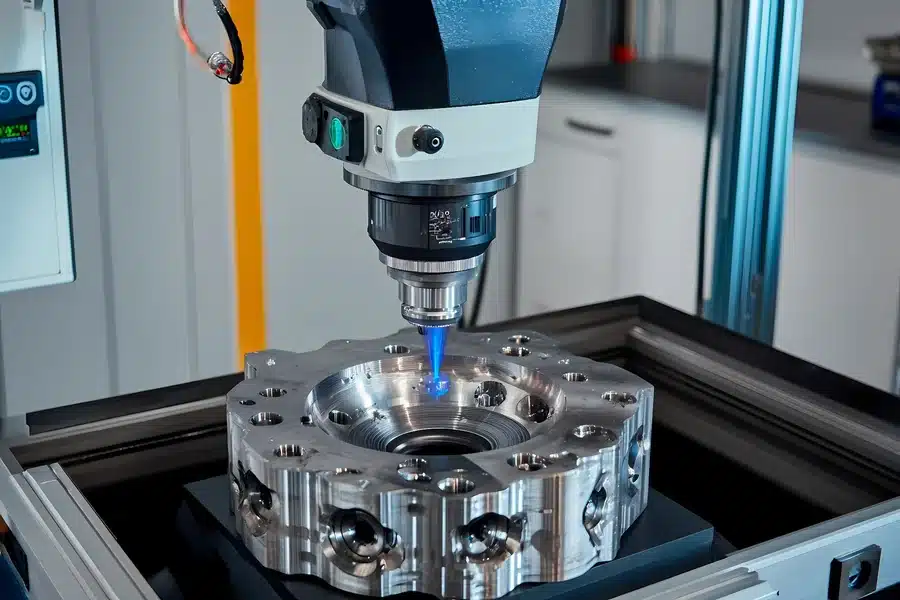

Precision motion control ensures that you get every cut, every grind, and every assembly step right. This gets even better when you employ the correct precision positioning stages or other technologies that fit the exact product you are working on.

These tools are often calibrated to give exact, repeatable movements that can lead to assembly with zero errors. The improved processes may translate to zero waste, lower the odds of making costly mistakes, and improve the overall quality of your finished product.

It Makes Products Smaller and More Efficient

Things are getting smaller and better over time. Take the example of your smartphone. It has billions of tiny transistors packed into its processor. How do manufacturers create those? With machines that move with nanometer-level precision.

Thanks to this tech, refined products use materials much more efficiently. There’s also less waste left over, and production costs are significantly lower. Also, smaller parts may mean less energy during operation. That’s good for the environment and cost-effective for the user.

It Keeps People Safe

Surgical robots are a great addition to the medical field today. They assist doctors during delicate operations, like heart surgery or tumor removal. But they have a zero margin for error.

If the robot’s arm moves even slightly off course, it could damage healthy tissue or cause complications. Precision movement significantly reduces the odds of this happening. But they aren’t the only tech with real-life implications.

Take a look at autonomous vehicles. These cars rely on precise motion control for steering, braking, and so on. A minor miscalculation in the movement of the wheels or the application of brakes could result in collisions. That’s dangerous to passengers and pedestrians. Precision motion control lowers the odds of such tragedies ever taking place.

It Boosts Efficiency and Saves Time

You may have been to a factory floor full of robots assembling cars, packaging food, or sorting packages. If those robots moved slowly, inaccurately, or inefficiently, production would come to a sputtering halt. Precision motion control is at hand to prevent that from happening.

For example, a robotic arm picking items in a warehouse doesn’t waste time swinging around unnecessarily. It calculates the shortest, most efficient path to grab what it needs. Multiply that efficiency across thousands of movements per day. What could that do to your productivity?

It Opens the Door for Innovation and New Possibilities

Sometimes, precision motion control isn’t just about fixing problems. It’s also about opening doors to new ideas. For example, 3D printing wouldn’t exist as it is without precise motion control. The printer head needs to move exactly where it’s supposed to, layer by layer, to create complex shapes.

This technology lets designers and engineers push boundaries. Need a custom prosthetic limb? A 3D printer can make it. Want to print a house? That can be arranged too.

It Builds Trust and Reliability

Think about insulin pumps for people with diabetes. These devices deliver precise doses of medication throughout the day. If the pump’s motor wasn’t controlled with extreme accuracy, it could give too much or too little insulin. That’s a patient’s health at risk.

Precision motion control guarantees the pump works reliably, every single time. It also helps ensure that every unit coming off the assembly line meets the same high standards. When machines are programmed to move with pinpoint accuracy, consistency becomes second nature.

Wrapping It Up

Precision motion control boils down to one thing: making things work better. Whether it’s improving product quality, taking efficiency to a whole new level, or ensuring safety, this technology shapes the world in more ways than one.

If it’s a solution your business could use, don’t hesitate. Do your research and settle for the options that best suit your needs and budget. This decision could be what takes your designs to the next level.